Monolithic Footings

2011-09-16

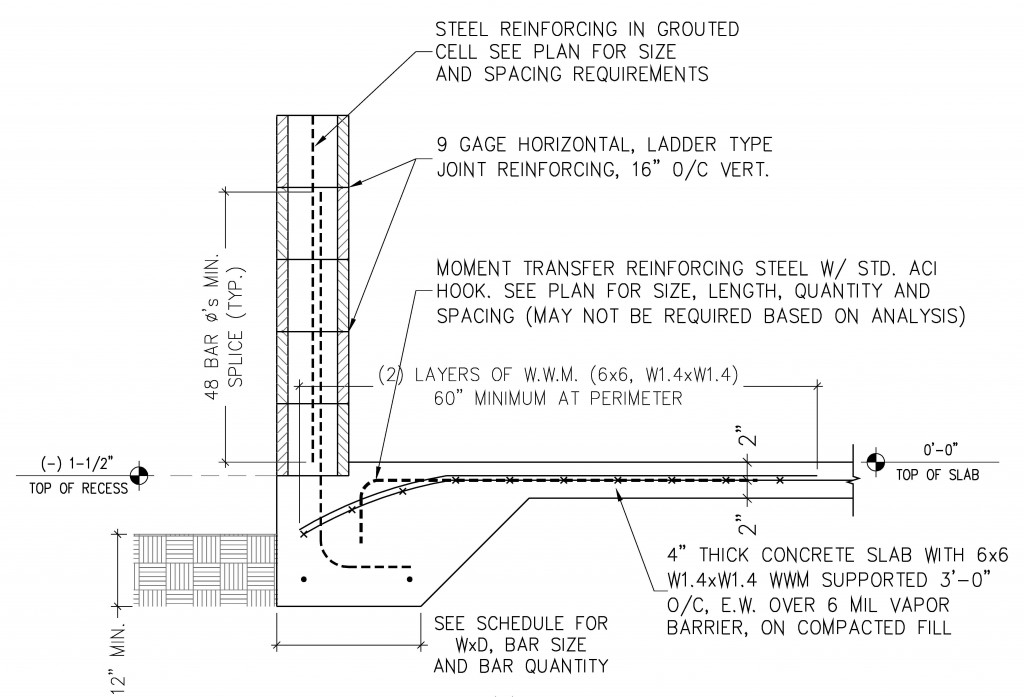

Monolithic footings are called “monolithic” or "mono" because the concrete is placed monolithically, or at the same time, as the slab. A monolithic footing is often simply a thickened area of concrete around the perimeter of a concrete slab on grade. There are no joints or separations between the footing and the slab. They most often support the exterior walls of the building, which are typically aligned with the outside edge of the mono footing. The footing provides a vertical exterior surface, at and continuous with the outside face of the wall, to the soil or exterior grade adjacent the home. A typical width and depth of monolithic footings is 16”, but this may vary with the local building code and the loads the footing is intended to support. Monolithic footings are often provided with a water-stop at the upper outside corner of the foundation. The water stop in this case is essentially a notch, upon or in which the exterior wall rests. The goal in this case is to make the horizontal interface (between the bottom of the wall and top of the footing) lower than the interior floor slab surface. This helps to direct any water (in or outside the wall) outward to the exterior. Steel reinforcement is usually provided in monolithic footings and varies with the design loads and building code in effect. The reinforcing steel provides strength and crack control, and typically consists of continuous or “longitudinal” steel bars placed near the bottom of the footing. They may also have shorter steel bars (the width of the footing minus several inches for concrete cover) placed, at regular intervals, perpendicular to and immediately above or below the longitudinal bars. These are sometimes referred to as “transverse” bars. Additional steel sometimes referred to as “transfer” bars may be provided around the slab perimeter, particularly at areas of higher exterior wall loading. This reinforcement steel often has a standard 90 degree hook located near the top outside corner of the footing / slab. The hooked bars are continuous for several feet back into the slab. Transfer steel is sometimes used with monolithic footings because of the eccentric or off-center loading condition of a monolithic footing. As mentioned above, the supported wall is most often aligned with the outside edge of the footing, and the monolithic footing width is invariably wider than the supported wall. This means that the load is eccentric, and a rotation potential exists. The transfer bars ‘transfer’ engage some of the slab, helping to prevent rotation of the footing. The construction of a monolithic footing and slab has the advantage of forming and placing concrete only once. If properly designed and constructed, monolithic footings suffice for the load bearing requirements of most one or two-story homes and even some light commercial buildings. A potential disadvantage of this type of footing is relatively limited load carrying capacity due to the eccentric loading conditions discussed above. The following is a sketch of a monolithic footing and adjacent slab. Note that transverse bars are not present in the detail: The following is a photograph of a newly placed monolithic footing and slab. The vertical steel bars protruding around the slab perimeter will lap with wall reinforcement in a grouted CMU cell. Note that a water stop "notch" was not provided at the slab perimeter: ADDITIONAL RESOURCES: ACI 117 - Standard Specification for Tolerances for Concrete Construction and Materials ACI 318 - Building Code Requirements for Structural Concrete ACI 332 – Residential Code Requirements for Structural Concrete