Prefabricated Wood Truss Roof Structure

2011-10-18

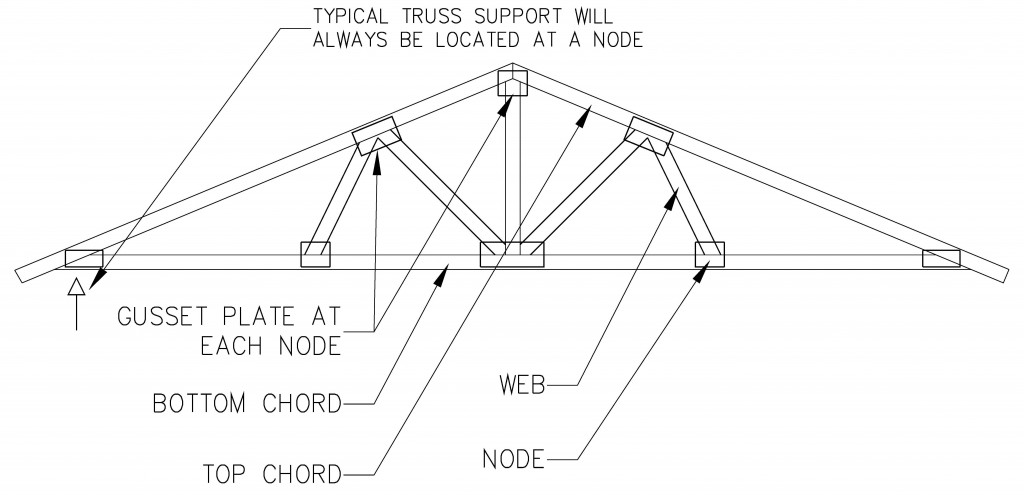

Wood trusses are often used for roof structures in single family homes and other relatively small buildings. Wood roof truss used in residential construction are composed of sawn lumber members that are assembled in such a way as to derive structural capacity from the depth of the truss. Trusses are widely used due to their strength to weight ratio and speed of construction. Today, most trusses are pre-engineered and prefabricated prior to shipment to the job site. A properly designed, constructed, installed, and protected roof truss whose capacity is not exceeded should last indefinitely. Problems may arise if any of these conditions are not met. Roof trusses are assembled in a multitude of differing shapes and sizes. Most roof trusses use 2x sawn lumber. The size of the members (chords and webs) typically vary between 2x4 and 2x8. Due to their strength, floor trusses are typically spaced farther apart than hand framed roof joists. A truss spacing interval of 24” is common. They can accommodate AC systems and even be fabricated to create small rooms within the trusses. Tray ceilings are sometimes formed by elevating the top chord of a roof truss. They can be assembled as one piece, or shipped as two or more individual components to be assembled on the job site. A roof truss has a top horizontal member (top chord), bottom horizontal member (bottom chord), and webs. The webs are orientated diagonally or vertically, and connect the top and bottom chords at intersections called nodes. The nodes are typically connected together with metal gusset plates, which are rectangular pieces of flat metal plate with jagged perforations that is pressed into the wood, joining the individual truss members together. General truss analysis assumes that the loading occurs only at the nodes, or joints between the webs and chords. It also assumes that the nodes are pinned connections, or that the bending restraint at the nodes is zero. This means that all truss members are assumed to be either in tension or compression, and no individual member is assumed to experience bending. Under normal gravity load conditions, the top chord is a compression member and the bottom chord is a tension member. The individual webs are either compression or tension members, depending upon their location within the truss. The webs and chords interact in such a way to gain structural benefit from the overall depth of the truss, or the distance between the top and bottom chords. The result is a relatively lightweight structural element that has a high load carrying capacity. Trusses are also relatively easy to accommodate plumbing, wiring, and attic space, due to the spaces between the chords and webs. As with any structural component, wood truss roof structures can only carry a finite load. Building codes requirements vary from state to state, county to county, and even between municipalities. Modern wood truss manufacturers typically have a structural engineer on staff, and the trusses are specifically designed to carry a certain design load. The trusses are generally shipped with a truss package which contains a truss placement plan and engineering data sheets for each individual truss. The truss placement plan indicates where each individual truss is to be placed in the structure. The data sheets specify the design load, dimensions, support reactions and locations, member and gusset plate sizes, and forces expected in the individual chords and webs. If properly designed and constructed, a wood truss roof system can be expected to safely carry the specified design load. The design load should be equal to or greater than that required by the building code in effect. A design load of 55 pounds per square foot of roof area is typical. This may increase dramatically in northern states where snow loads are present. Even without damage, the load carrying ability of wood roof trusses vary widely from home to home. Not all wood roof trusses in use today were designed by a structural engineer. This is particularly true of older homes. Trusses were sometimes assembled by the builder on site. In years past, truss manufacturers did not always hire an engineer to design their trusses. Older trusses were often constructed based on the fabricator's knowledge of "what worked", or in consultation with engineers on the staff of gusset plate manufacturers. In addition, building codes have changed significantly over the years. All this does not mean that roof trusses in older homes are unsafe or in any way defective. However, it illustrates that the capacity of older wood trusses varies widely. When compared with a hand framed wood roof structure, a wood truss roof has the advantage of high strength to weight ratio, and the construction speed which comes from a component pre-assembled to fit the home under construction. They also have the advantage of being easier to place utility lines, such as electric wires, heating ducts, and plumbing. There is usually more lead time involved as they are usually pre-ordered and specifically designed for the home under construction. The following is a sketch indicating the basic components of a prefabricated wood roof truss: The following is a photograph of prefabricated wood roof trusses delivered to a construction site. Note that the trusses have been unloaded and are being temporarily stored on rough terrain. The uneven ground surface has resulted in excessive bending of the trusses. This is particularly true on the right hand side, where the trusses are virtually unsupported: The following photograph shows installed roof trusses with roof sheathing in progress: ADDITIONAL RESOURCES: ANSI/TPI 1 - National Design Standard for Metal Plate Connected Wood Truss Construction National Design Specification for Wood Construction Timber Construction Manual