Prefabricated Wood Truss Floor Structure

2011-09-19

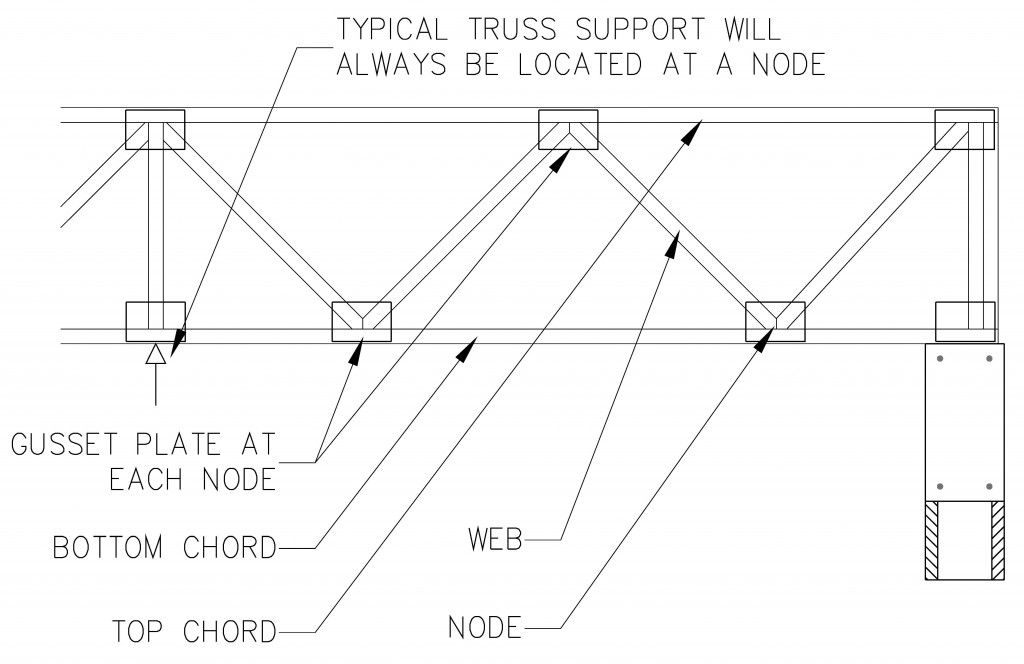

Wood trusses are often used for floor structures in single family homes and other buildings. Most wood floor trusses used in residential construction are composed of sawn lumber that is assembled in such a way as to derive structural capacity from the depth of the truss. Trusses are widely used due to their strength to weight ratio as compared with sawn lumber joists. Today, most trusses are pre-engineered and prefabricated prior to shipment to the job site. The structure of a typical wood truss floor structure typically involves three primary structural components. The first of these is the subfloor decking (or sheathing). The term "subfloor" refers to the structure beneath the finished, exposed flooring. The floor deck or sheathing spans across and is supported by the floor trusses. It is sometimes visible when finished flooring (such as vinyl or carpet) is pulled up. The second primary component of a wood truss floor structure is the floor trusses. Floor trusses are spaced at regular intervals and are typically prefabricated and delivered to the job site. In some floor structures, floor truss girders (or beams) support the floor trusses and if existing, could be considered the third primary component of a floor structure. Finally, the girders and or trusses are supported by load bearing walls and or columns. The load bearing walls may be exterior (perimeter) walls, or located at the interior. Columns are often used to support heavy gravity loads carried by beams. A properly designed, constructed, installed, and protected floor truss system whose load bearing capacity is not exceeded will serve the life of a home. Problems may arise if any of these conditions are not met. Floor decking typically consists of sheathing (plywood or orientated strand board (OSB)) or sawn lumber. The decking spans over the trusses, and therefore must be of sufficient strength and stiffness to transfer any point load to adjacent trusses without failure or excessive deflection. Wider truss spacing requires thicker and stronger floor decking. The thickness of plywood or OSB sheathing varies with the type and application, but 3/4" is common for floor decking. Sawn wood planks (boards), 1-1/2” thick, are also commonly used for floor decking. The width of the individual floor planks is significant with regards to point loads. When loads are applied over an area, 2x4 decking is as capable as 2x6 or 2x8 decking. However, if a point load happens to be applied to only one board, then a wider board is obviously stronger than a narrow board. This concept is not as significant if adjacent floor planks interlock with each other by a tongue and groove mechanism. This has several advantages: point loads are transferred to adjacent boards and movement is restrained across the boards, resulting in a quieter, tighter, and smoother floor. A floor truss (and truss girder) has a top horizontal member (top chord), bottom horizontal member (bottom chord), and webs. The webs are orientated diagonally or vertically, and connect the top and bottom chords at intersections called nodes. The nodes are typically connected together with metal gusset plates, which are rectangular pieces of flat metal plate with jagged perforations that is pressed into the wood, joining the individual truss members together. Due to their high capacity, floor trusses are typically spaced farther apart than sawn lumber joists. Truss spacing intervals of 16” to 24” are common. Depending upon the expected loads, span, and spacing, they may range from 9” to 32” inches or more in depth, although a typical residential truss depth range is 12” to 24”. A floor truss can either be bottom or top chord bearing. Top chord bearing trusses are “hung” over the top of a wall, foundation, ledger or other support. Top chord bearing floor trusses have a diagonal web member located between the bearing point and the remaining bottom chord. This web is necessary for a continuous tensile load path. Bottom chord bearing trusses are placed directly atop the support. General truss analysis assumes that the loading occurs only at the nodes, or joints between the webs and chords. In reality this is not the case, as the top and bottom chords of floor (and roof) trusses obviously receive distributed loads. Truss analysis also assumes that the nodes are pinned connections, or that the bending restraint at the nodes is zero. This means that all truss members are assumed to be either in tension or compression, and no individual member is assumed to experience bending. Under normal gravity load conditions, the top chord is a compression member and the bottom chord is a tension member. The individual webs are either compression or tension members, depending upon the loading and layout of the truss. The webs and chords interact in such a way to gain structural benefit from the overall depth of the truss, or the distance between the top and bottom chords. The result is a relatively lightweight structural element that has a high load carrying capacity. Trusses are also relatively easy to accommodate plumbing, wiring, and HVAC equipment, due to the spaces between the chords and webs. As with any structural component, wood truss floor structures can only carry a finite load. Building codes requirements vary from state to state, county to county, and even between municipalities. Modern wood truss manufacturers typically have a structural engineer on staff, and the trusses are specifically designed to carry a certain design load. The trusses are generally shipped with a truss package which contains a truss placement plan and engineering data sheets for each individual truss. The truss placement plan indicates where each individual truss is to be placed in the structure. The data sheets specify the design load, dimensions, support reactions and locations, member and gusset plate sizes, and forces expected in the individual chords and webs. If properly designed and constructed, a wood truss floor system can be expected to safely carry the specified design load. The design load should be equal to or greater than that required by the building code in effect. A design load of 55 pounds per square foot of floor area is a typical design load. However, much has changed over the last several decades. The load carrying ability of wood floor trusses vary from home to home. Not all wood floor trusses in use today were designed by a structural engineer. This is particularly true of older homes. Trusses were sometimes assembled by the builder on site. In years past, truss manufacturers did not always hire an engineer to design their trusses. Older trusses were often constructed based on the fabricator's knowledge of "what worked", or in consultation with engineers on the staff of gusset plate manufacturers. In addition, building codes have changed significantly over the years. All this does not mean that floor trusses in older homes are unsafe or in any way defective. Floor trusses are supported by beams, load bearing walls, or truss girders. Truss girders may be considered "beams" that support multiple floor trusses. Their increased capacity is achieved by using multiple plies, larger chords and webs, or a combination of these. Similar to an individual floor truss, the girders may bear on the top, or be attached to the side of a beam, wall or column. The girder size and construction is determined by its unsupported length, or span, and the tributary area of the floor truss it supports.

When compared with a hand framed wood floor structure, a wood truss floor has the advantage of high strength to weight ratio, and the construction speed which comes from a component pre-assembled to fit the home under construction. They also have the advantage of being easier to place utility lines, such as electric wires, heating ducts, and plumbing. However, they are typically deeper than wood framed joists, and thus use more vertical space within the home. In addition, there is lead time involved as they are usually pre-ordered and specifically designed for the home under construction.

Finish flooring such as carpet, tile, or vinyl is applied to and supported by the floor decking or sheathing. The finish flooring generally has no structural support value and is not considered to be a part of the ‘floor structure’. However, it can be affected by a problem with the floor structure, and vice versa.

The following is a sketch indicating the basic components of a prefabricated wood floor truss:

The following is a photograph of recently installed floor trusses supported by an exterior CMU wall. The girder truss on the right side of the picture supports the perpendicular trusses. Note that the girder truss is a double ply and the truss members are orientated vertically rather than horizontally. The discoloration visible at the underside of the OSB floor sheathing was the result of the floor structure being exposed to rain prior to the roof installation:

ADDITIONAL RESOURCES:

ANSI/TPI 1 - National Design Standard for Metal Plate Connected Wood Truss Construction

National Design Specification for Wood Construction

Timber Construction Manual